REP

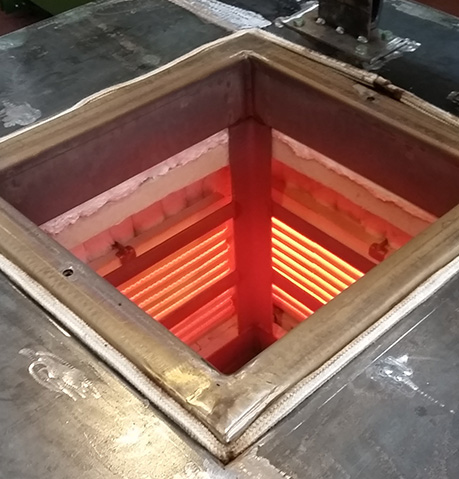

INDUSTRIAL PIT OVEN

In the range of CTM products for the pyrolytic treatment, we introduce the model REP, a pit furnace constructed internally with stainless steel sheet.

Direct or indirect heating is obtained by means of sets of electric resistances positioned uniformly on the walls of the furnace.

In the range of CTM products for the pyrolytic treatment, we introduce the model REP, a pit furnace constructed internally with stainless steel sheet.

Direct or indirect heating is obtained by means of sets of electric resistances positioned uniformly on the walls of the furnace.

To complete the manufacturing process we supply flue gas stacks with the possibility of direct connection to the post combustion chamber.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Cover opening/closing system: manual or servo-assisted.

Operation

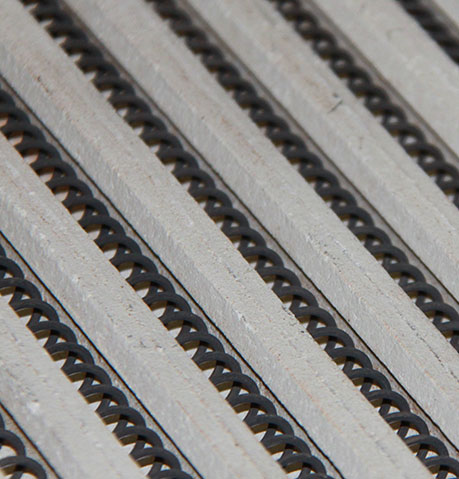

The operation of these furnaces in filters and die plate packs cleansing is based on the process of "PYROLYSIS" according to which the hydrocarbon molecules, less stable if subject to heat, when subjected to certain thermal cycles, break (cracking) giving rise to simpler gaseous molecules.

In our case the pyrolysis obtained from the polymer which coats the parts, while a complete incineration process is realized, generates combustible gases which are subsequently brought to complete oxidation in the post-combustion chamber generating products perfectly suitable for release into the atmosphere.

- Pyrolytic treatment in reducing atmosphere

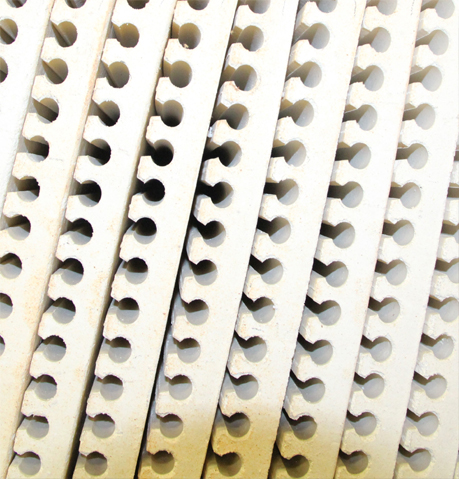

- Cleansing of packs and die plates

- Cleansing of filters

- Cleaning of extrusion screws

Post-combustor.

Stainless steel baskets.

| Model REP |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| REP/0 | 300 | 300 + 150 | 300 | 6 | 27 |

| REP/1 | 500 | 450 + 150 | 500 | 8 | 113 |

| REP/2 | 300 | 300 + 150 | 1500 | 12 | 135 |

| REP/3 | 500 | 450 + 150 | 650 | 16 | 146 |

| REP/4 | 500 | 500 + 150 | 750 | 18 | 187 |

| REP/5 | 300 | 300 + 150 | 2100 | 20 | 189 |

| REP/6 | 650 | 500 + 150 | 650 | 24 | 211 |

| REP/7 | 500 | 500 + 150 | 1000 | 26 | 250 |

| REP/8 | 600 | 500 + 150 | 1000 | 30 | 300 |