For the post curing and vulcanization process of natural rubber, CTM proposes the model GVS, a ventilated chamber oven whose metal structure features air circulation with walls made of stainless steel sheet and insulating material.

The oven chamber is heated with electric heating units or with indirect heat exchangers powered by gas, methane or fuel oil burners.

Forced air circulation takes place by means of special fans suitable for high temperatures. Circulation is optimized by flow rate adjusters.

We can provide several versions with closed or open loop or with horizontal or vertical split currents.

A manual or servo-assisted control manages the throttle valves for air input and output.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Door opening: with hinge or counterbalanced guillotine with manual or servo-assisted handling system.

If required, precision instrumentation that will allow the control of the cooling cycle can be installed.

- Post curing of seals and Viton O-rings

- Post curing of seals and Silicone O-rings

- Post curing of seals and Epdm O-rings

- Post curing of seals and Nbr O-rings

- Vulcanization of profiles of technical rubber items

Hood positioned on the door.

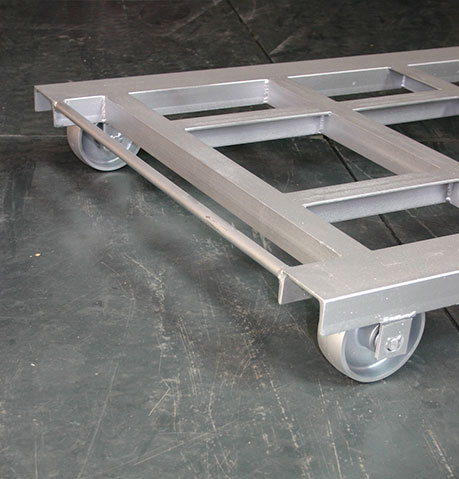

Dollies with mobile or fixed shelves in stainless steel sheet.

| Model GVS |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| GVS/3 | 700 | 900 | 800 | 6 | 504 |

| GVS/4 | 850 | 1000 | 1000 | 9 | 850 |

| GVS/5 | 1000 | 1000 | 1300 | 12 | 1300 |

| GVS/5RT | 1000 | 1400 | 1400 | 12 | 1960 |

| GVS/6 | 1000 | 1000 | 2000 | 18 | 2000 |

| GVS/7 | 1200 | 1500 | 2000 | 32 | 3600 |

| GVS/8 | 1500 | 1800 | 2000 | 36 | 5400 |