REV

INDUSTRIAL VENTILATED CHAMBER OVEN

Our model REV is an optimal solution for those companies who are looking for a ventilated chamber oven for processes of tempering, annealing, ageing in combination with processes for molds preheating or related products.

Our model REV is an optimal solution for those companies who are looking for a ventilated chamber oven for processes of tempering, annealing, ageing in combination with processes for molds preheating or related products.

The air circulation metal structure with walls made of stainless steel sheet constitutes the high thickness air recirculation gap while the inner chamber is made of stainless steel.

The useful dimensions of the latter are available in the table below.

Chamber heating is obtained electrically with resistance units positioned on special media or by direct or indirect heat exchangers powered by gas, methane or fuel oil burners.

Ventilation is of horizontal type to ensure a good treatment uniformity.

Air circulation optimization is realized by flow adjustments.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Throttle valves for air input and output with manual or servo-assisted adjustment.

- Door opening: with hinge or counterbalanced guillotine with manual or servo-assisted handling system.

If required, precision instrumentation that will allow the control of the cooling cycle can be installed.

- Tempering Process

- Annealing process by softening

- Ageing Process

- Springs treatment

- Preheating of molds components

- Preheating of die plate packs

- Preheating of filters

- Preheating of extrusion screws

Hood positioned on the door.

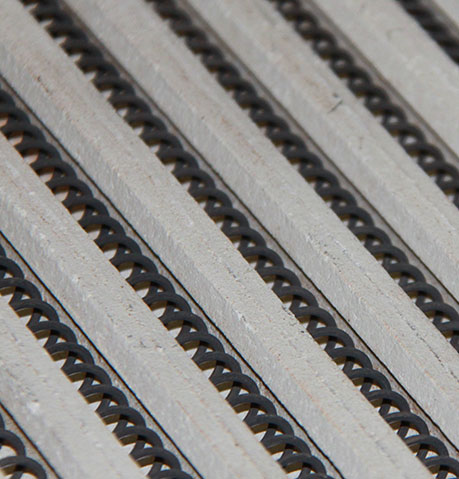

Dollies with mobile or fixed shelves in stainless steel sheet.

Specific equipment for individual needs.

| Model REV |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| REV/0 | 300 | 300 | 400 | 8 | 36 |

| REV/1 | 400 | 400 | 500 | 10 | 80 |

| REV/2 | 500 | 500 | 500 | 12 | 125 |

| REV/3 | 600 | 600 | 700 | 15 | 252 |

| REV/4 | 750 | 600 | 750 | 18 | 337 |

| REV/5 | 1000 | 750 | 1000 | 24 | 750 |

| REV/6 | 1000 | 1000 | 1200 | 35 | 1200 |