VAT

INDUSTRIAL VENTILATED CHAMBER OVEN

The ever-increasing use in the industrial field of titanium has motivated our company to design a specific line for its thermal process, called VAT.

The ever-increasing use in the industrial field of titanium has motivated our company to design a specific line for its thermal process, called VAT.

Basically, chamber heating is obtained by electrical resistances units positioned on dedicated supports; however, taking into account the significant requests and subsequent installations carried out, we have optimized an efficient heating process using direct or indirect heat exchangers powered by gas, methane or fuel oil burners.

Through a manual or servo-assisted adjustment of the installed valves, it is possible to establish, for your industrial process, the optimal air flow in the input and output process.

Ability to control the cooling cycle with precision instrumentation.

- Horizontal ventilation; optimisation of air circulation with flow adjustments.

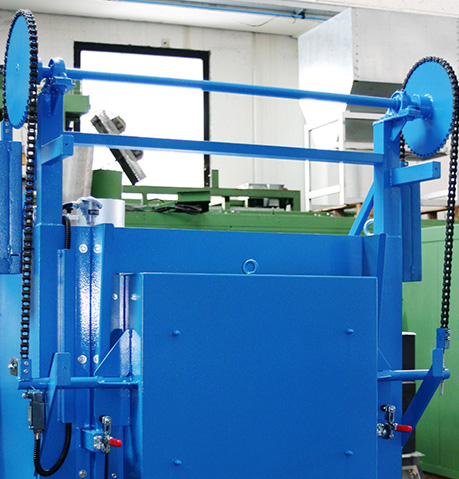

- Door opening: with hinge or counterbalanced guillotine with manual or servo-assisted handling system.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Titanium Treatment

Hood positioned on the door.

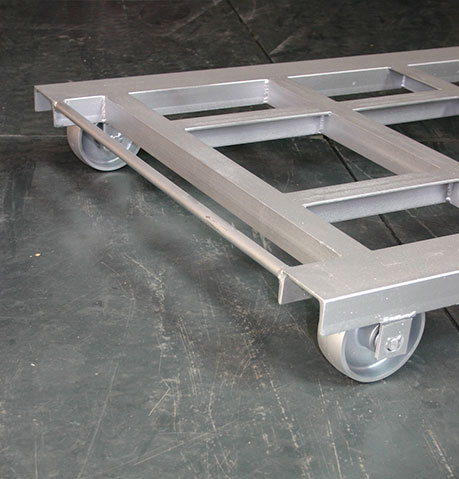

Manual or motorized dollies with movable or fixed shelves.

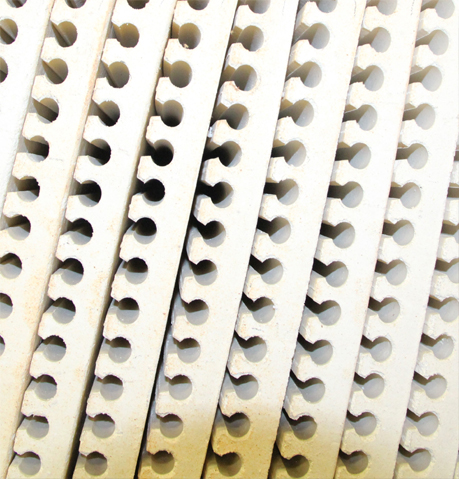

Shelves, crates and roller conveyors.

| Model VAT |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| VAT/0 | 600 | 600 | 1000 | 30 | 360 |

| VAT/1 | 1000 | 1000 | 1500 | 70 | 1500 |

| VAT/2 | 1500 | 2000 | 2800 | 200 | 8400 |

| VAT/3 | 1800 | 1900 | 3500 | 300 | 12000 |

| VAT/4 | 1800 | 2000 | 4000 | 350 | 14400 |