PT MBT

INDUSTRIAL VENTILATED CHAMBER OVEN

Our model MBT, belonging to the line "PT" for polymers treatment, arises from the need to optimize the sintering process of the PTFE-product taking into account the variables "Size and Shape", all related to the thermal phase.

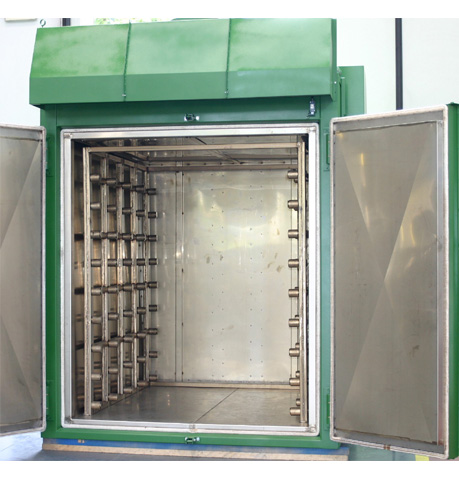

Our model MBT, belonging to the line "PT" for polymers treatment, arises from the need to optimize the sintering process of the PTFE-product taking into account the variables "Size and Shape", all related to the thermal phase. The metal structure, with chamber or tunnel, with air circulation, has walls of stainless steel sheet that constitute the heat absorbing, high thickness sandwich with cavity for air circulation.

Sets of electrical resistances with low surface load and high exchange power positioned in the air circuit process the heating phase.

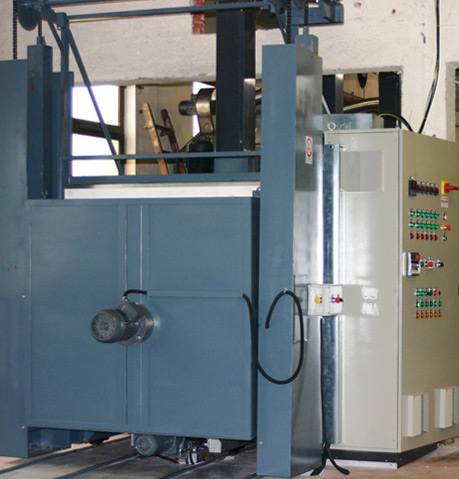

Air entry and exit is controlled by butterfly valves, either manually or in a servo-assisted mode

- Versions per closed or semi-closed loop with horizontal/vertical split currents.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Forced air circulation takes place by means of special fans suitable for high temperatures; optimisation of the circulation with flow rate adjusters.

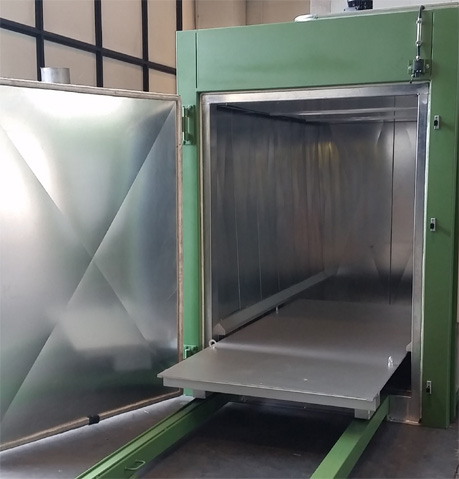

- Door opening: with hinge or counterbalanced guillotine with manual or servo-assisted handling system.

- Sintering of technical articles in PTFE

- Sintering of manufactured items and blocks in PTFE

- Sintering of PTFE sleeves

- Sintering PTFE coating tubing

Hood positioned on the door.

Dollies with mobile or fixed shelves in stainless steel sheet.

Specific equipment for individual needs.

| Model PT MBT |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| PT MBT/1 | 1200 | 1200 | 1200 | 24 | 1730 |

| PT MBT/2 | 1200 | 1200 | 1700 | 32 | 2450 |

| PT MBT/3 | 1300 | 1500 | 1700 | 40 | 3315 |

| PT MBT/4 | 1600 | 1850 | 1700 | 65 | 5032 |

| PT MBT/5 | 2000 | 1900 | 1700 | 72 | 6460 |

| PT MBT/6 | 1900 | 2000 | 2300 | 90 | 8740 |