TR

INDUSTRIAL VENTILATED CHAMBER OVEN

CTM has been for many years a point of reference for resins heat treatment in the electrical engineering industry. The main model for this application is called TR and on it structure, over the years, multiple applications have been developed taking into account the needs and specifications of the customers.

CTM has been for many years a point of reference for resins heat treatment in the electrical engineering industry. The main model for this application is called TR and on it structure, over the years, multiple applications have been developed taking into account the needs and specifications of the customers.

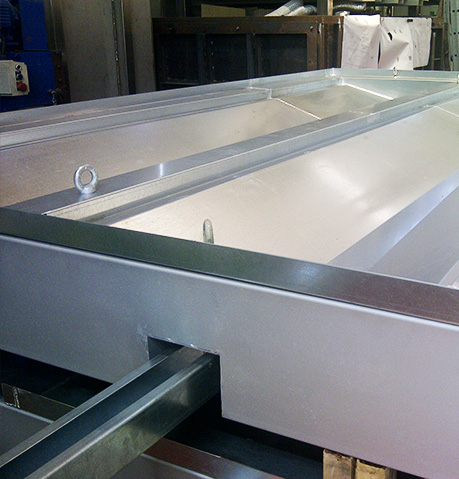

TR has an air circulation metal structure with walls made of stainless steel sheet.

Special fans combined with electrical resistance units or indirect heat exchangers powered by gas, methane or fuel oil burners, ensure inner chamber temperature homogeneity.

Flow regulators optimize circulation.

We have several versions: for closed loop, half open loop and with horizontal and vertical split currents.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Throttle valves for air input and output with manual or servo-assisted adjustment.

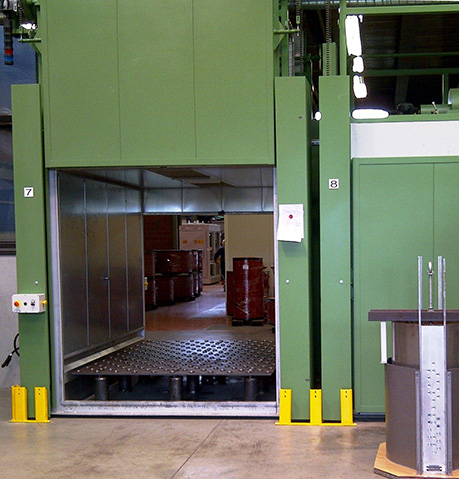

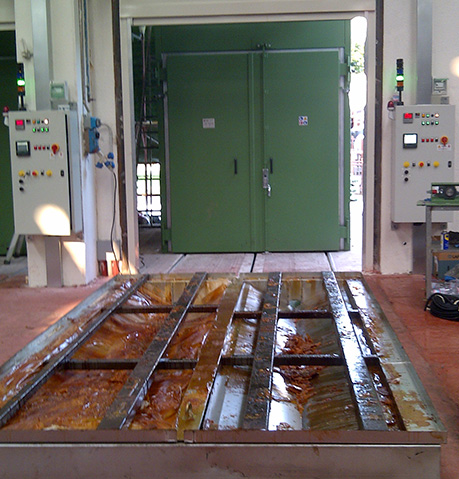

- Door opening: with hinge or counterbalanced guillotine with manual or servo-assisted handling system.

- Resins treatment

- Resins polymerization

- Transformers columns drying

- Oil transformers drying

- Motors drying

- Coils drying

- Treatment of inductance coils

- Treatment core transformer

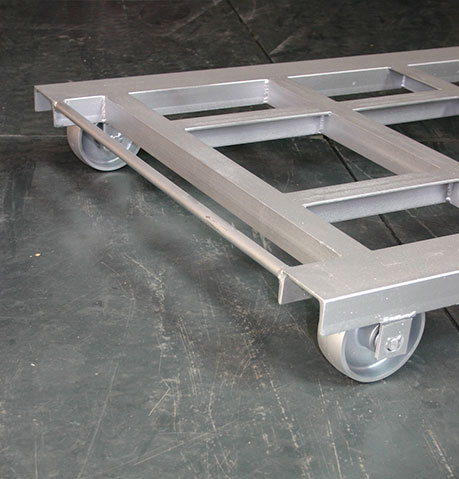

Manual or motorized rack dollies with movable or fixed shelves.

Cooling with electrical aspirator for rapid decrease in temperature in the chamber.

| Model TR |

Useful dimensions of the chamber | Rated power | Capacity | ||

| Width | Height | Depth | Kw | Lt | |

| TR/220H2 | 2000 | 2000 | 2000 | 24 | 8000 |

| TR/225H2 | 2000 | 2000 | 2500 | 30 | 10000 |

| TR/230H2 | 2000 | 2000 | 3000 | 36 | 12000 |

| TR/235H2 | 2000 | 2000 | 3500 | 42 | 14000 |

| TR/240H2 | 2000 | 2000 | 4000 | 54 | 16000 |