DL

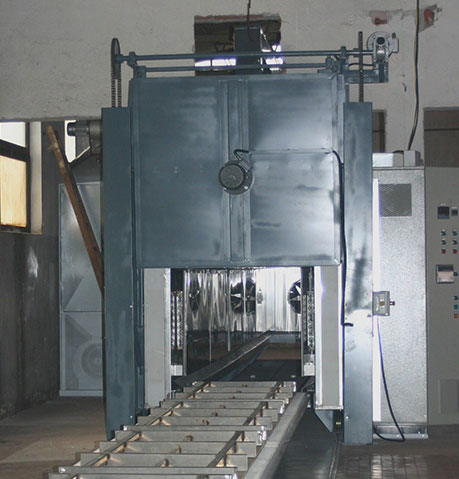

INDUSTRIAL TUNNEL FURNACE WITH VENTILATED CHAMBERS

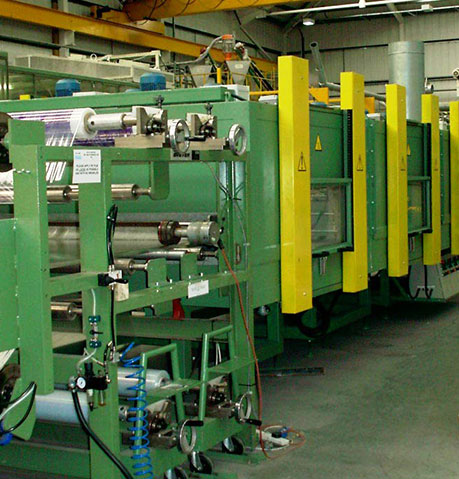

Our modular tunnel with ventilated chambers enables to determine the optimal length of the sheets to achieve an efficient hourly production of extrusion.

Our modular tunnel with ventilated chambers enables to determine the optimal length of the sheets to achieve an efficient hourly production of extrusion.

Designed to obtain a straightening of polycarbonate sheets of non-standard dimensions, the tunnel furnace was also appreciated in other applications for plastics.

The external structure is realized with walls made of galvanized carbon steel sheets while electrical heating takes place via sets of resistances located in the interspace for air circulation.

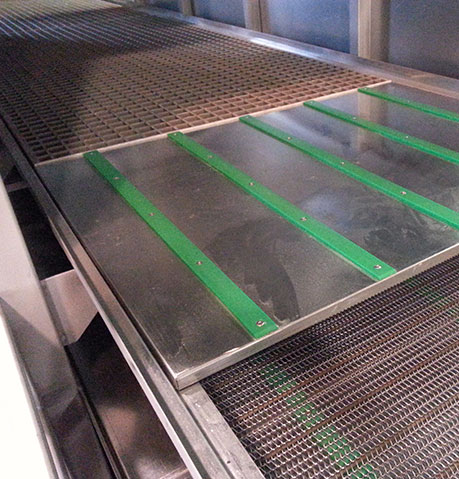

Air ventilation is obtained through special motors for high temperatures that allow a homogeneous aeration both above and below the sheet, while butterfly valves, with manual or servo-assisted control, process air entry/exit.

- Electronic adjustments of temperature through static power relays with the possibility of programming and data logging.

- Service doors with opening upwards provided with double safety glass.

- Interior lighting in the treatment chamber.

- Straightening Polycarbonate - methacrylate - plastics

- Tempering Polycarbonate - methacrylate - plastics

| Model DL |

Useful dimensions of the chamber | Rated power | ||||

| Width | Height | Oven Standard Lenght with 3 section | Extra section lenght | Kw – Standard oven | Kw – Extra section | |

| DL/1100 | 1350 | 200 + 200 | 6600 | 2200 | 144 | 48 |

| DL/1250 | 1600 | 200 + 200 | 6600 | 2200 | 144 | 48 |

| DL/2100 | 2350 | 200 + 200 | 6600 | 2200 | 216 | 72 |

| DL/2500 | 2750 | 200 + 200 | 6600 | 2200 | 216 | 72 |